Other

Description

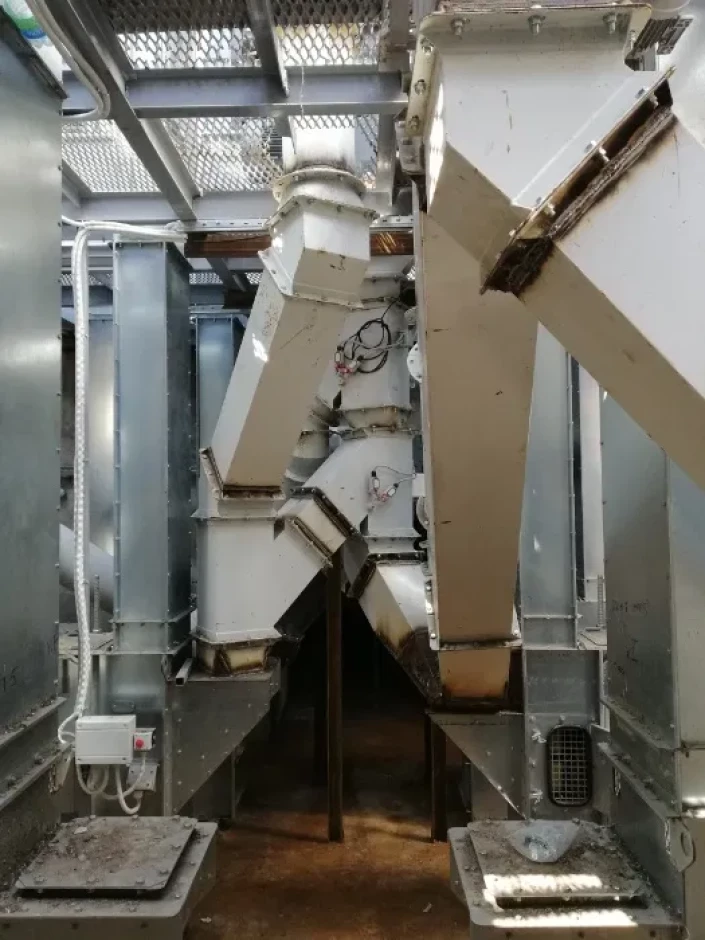

We produce bucket elevators with a capacity from 5 to 1000 tons per hour, and the product can be equipped with buckets with a capacity of 0.3 to 8.1 dm. Both metal and polymer materials can be used to make buckets. Buckets made of polymers have a low weight and minimally injure grain thanks to the elastic edge on the loading part of the bucket. All manufactured elevator installations are equipped with the following sensors: transport speed control; to monitor the tape coming off the reels; to measure the head pressure of the material being moved. In the event of foreign objects entering the elevator or in another emergency situation, these sensors will give a signal to stop the mechanism. All models are necessarily equipped with an explosion arrester unit, which, in the event of an explosion of the dust mixture formed during the movement of bulk materials, “dumps” the blast wave into the environment. In this case, the box and mechanisms of the elevator do not receive damage, and to continue operation it is only necessary to replace the polymer bursting disc in the explosion arrester. Our company produces bucket elevators in two versions: standard and self-supporting. Standard elevators are used as supporting elements of the structure of elevators and grain drying complexes. This simplifies and reduces the cost of the unit design. The design of self-supporting elevators allows them to be installed as independent technological units, but this requires the installation of separate metal structures for service platforms and stairs. Technical advantages of bucket elevators: increased service life; compatibility with any automation system; the presence of a monitoring system that minimizes the intervention of service personnel; energy-saving drive (provides up to 30% energy savings); built-in security systems; ease of maintenance and repair; complete sealing of components; the use of lining on the inlet and outlet pipes (provides wear resistance to the metal parts of the elevator at the points of contact between the metal and the grain); bearing units from leading manufacturers; possibility of using polymer buckets; delivery without the use of specialized transport; simple and quick installation; the smallest percentage of grain injury during movement. In addition to manufacturing a variety of equipment, we offer services for the design and installation of elevator equipment, as well as the modernization and reconstruction of existing grain storage and processing enterprises in Kazakhstan. Call and/or write to WhatsApp

Characteristics

Batch, tons 1

Seller

ТОО "Технологика Н" Company On the website since 15.02.2024

Location

Leave a comment