Equipment for processing fruits and vegetables

Description

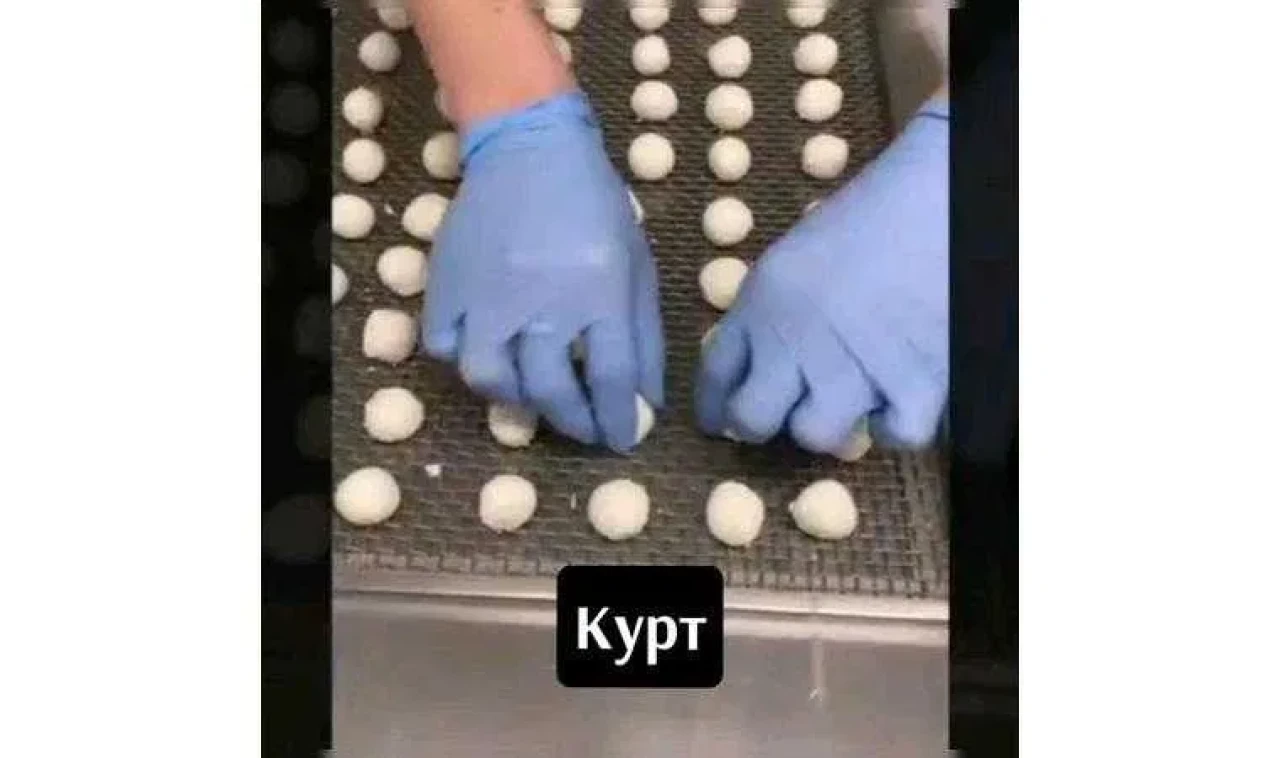

Industrial convection drying chamber T120-18. There is an installment plan for the Caspian Sea. designed for drying products at specified temperature conditions: Fruits, vegetables, citrus fruits, Kurt berries. Pasta Mushrooms, tea, herbs, nuts Drying (drying) - meat, chicken, fish, minced meat, pet treats Snacks, chips, frips, slices, marshmallows, crackers Other food raw materials Fresh air constantly enters the operating drying chamber. Passing through the thermal block, it reaches the required temperature and is evenly supplied to the trays. A special feature of the chamber is a uniform supply of air to all trays, regardless of their location in the chamber. This directly affects the duration and quality of drying. In the main air duct, next to the trays, special outlets with air dividers are installed. This system ensures uniform movement and distribution of air in the dryer. Air saturated with moisture during the drying process is removed through the exhaust ventilation module included in the kit. The intensity of the hood can be adjusted using a damper and a special regulator. You can set the required temperature and drying time using the control module. This device easily monitors the remaining operating time, as well as the temperature and humidity** of the air inside the chamber. It informs about the completion of the process with a sound signal and independently puts the equipment into standby mode. To increase the functionality of the camera, additional devices are installed that allow you to use the following modes: delay start; cyclicity and temperature changes; downtime and weathering; maintaining air humidity according to the required parameters**. Technical characteristics: Temperature range from +35°C to +120°C Connection 220 V Power max/average 6.5 kW / 4 kW Drying time average* from 2 to 10 hours *actual drying time is individual and depends on the raw material, cutting thickness , drying temperature, required residual moisture Number of racks/trays 18 pieces Total useful area of trays 8 sq.m. Characteristics of the elbows included trays with a mesh made of food-grade aluminum, size (L*W*H, in mm) 600*700*20, cell 4*8mm, load up to 3 kg per tray Chamber loading (depending on raw materials, cutting thickness, initial humidity) With food grade aluminum trays - 3kg*18 trays = 54 kg, Distance between trays on racks from mesh to mesh 55 mm Dimensions of the chamber assembly with exhaust ventilation (L*W*H, in mm) 84****** ***20, weight with trays up to 180 kg Includes: thermostat, time timer, temperature sensor, exhaust ventilation regulator, internal ventilation regulator, toggle switch for turning on power mode 3 kW to 6 kW, adjustment of air flows inside the chamber, slide damper, exhaust fan, corrugation under exhaust ventilation.

Characteristics

Batch, tons 1

Seller

Location

Leave a comment